About us

Welcome

My name is Nick Verwaal, the founder and artist behind MAPLAB.

The story behind MAPLAB started in 2020 when I was experimenting with hardwood as a design material, combining fabrication technologies with my interest in cartography. My goal was to make these maps out of hardwood as delicate and detailed as if they were drawn on paper. While adding a 3D aspect and integrating the look of hardwood and heavy parchment.

This journey led to the integration of my own machines to cut the designs using both CNC technology and the developments in laser diode technology. My customers love the three dimensional detail, the addition of greenery and the ability to recognize their streets and favorite places in an item made out of hardwood and specialty paper.

Now we are on a journey to create bespoke topographic art which sparks curiosity, brings a sense of belonging and is simply spectacular in any space. We believe strongly in sustainable business and therefore plant a tree for any map purchased.

I’m looking forward to create a truly magnificent design for your home, office or as a unique gift.

Nick Verwaal,

Delft

A visual tour through the design and creation process

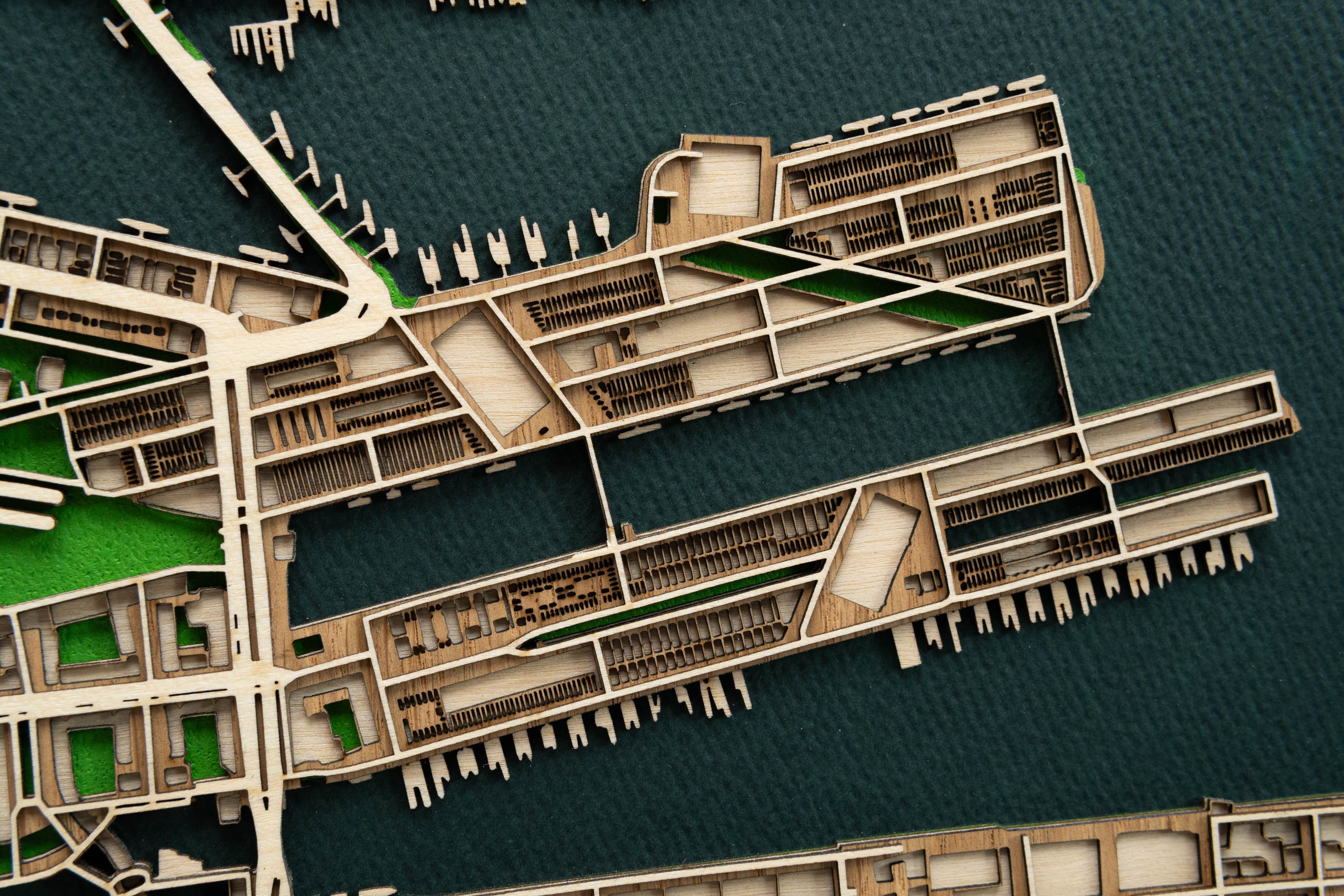

Eastern Docklands in Amsterdam

Conceptual phase

- Understand the topology of the area with the help of some aerial pictures and satellite images.

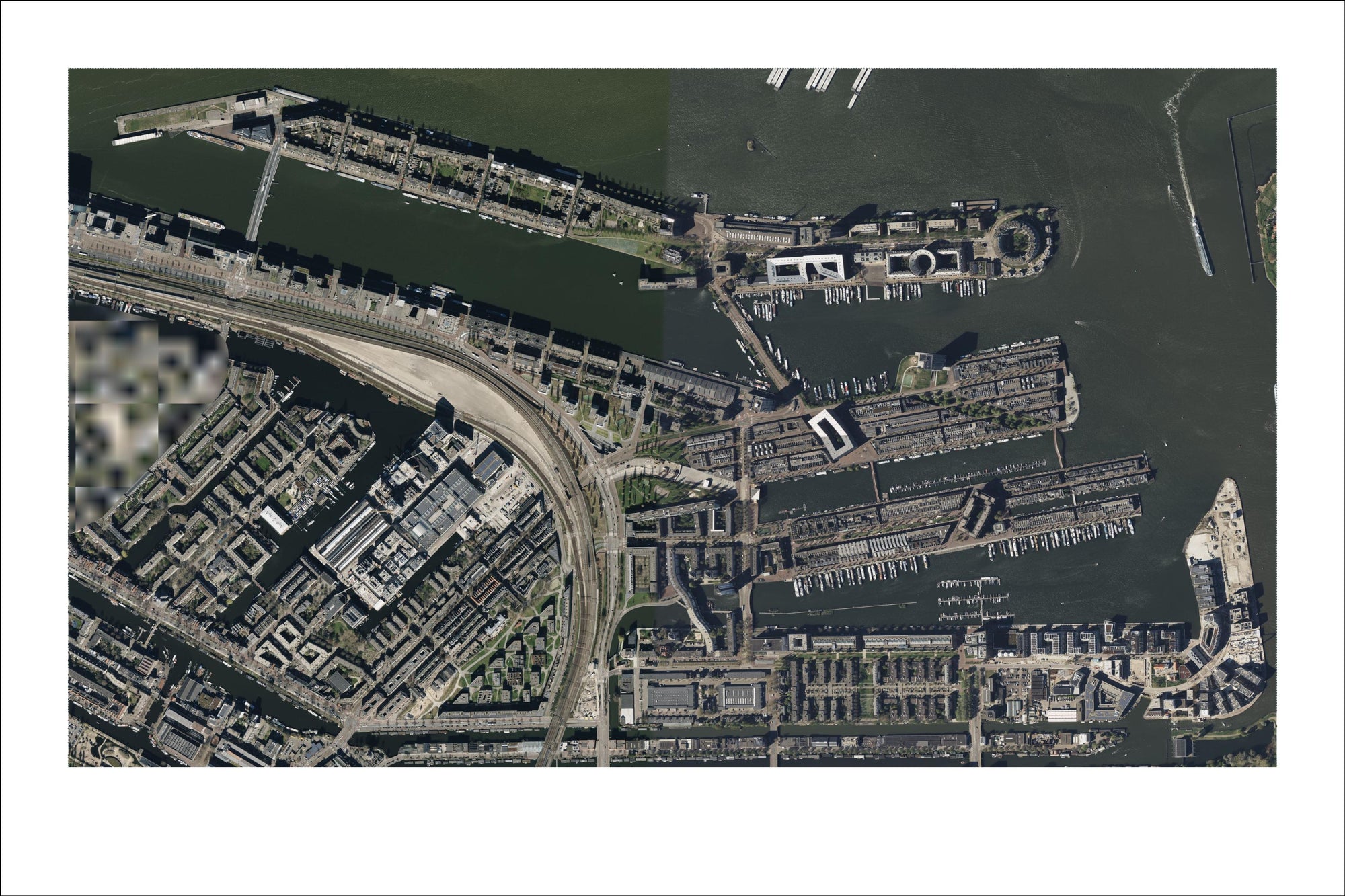

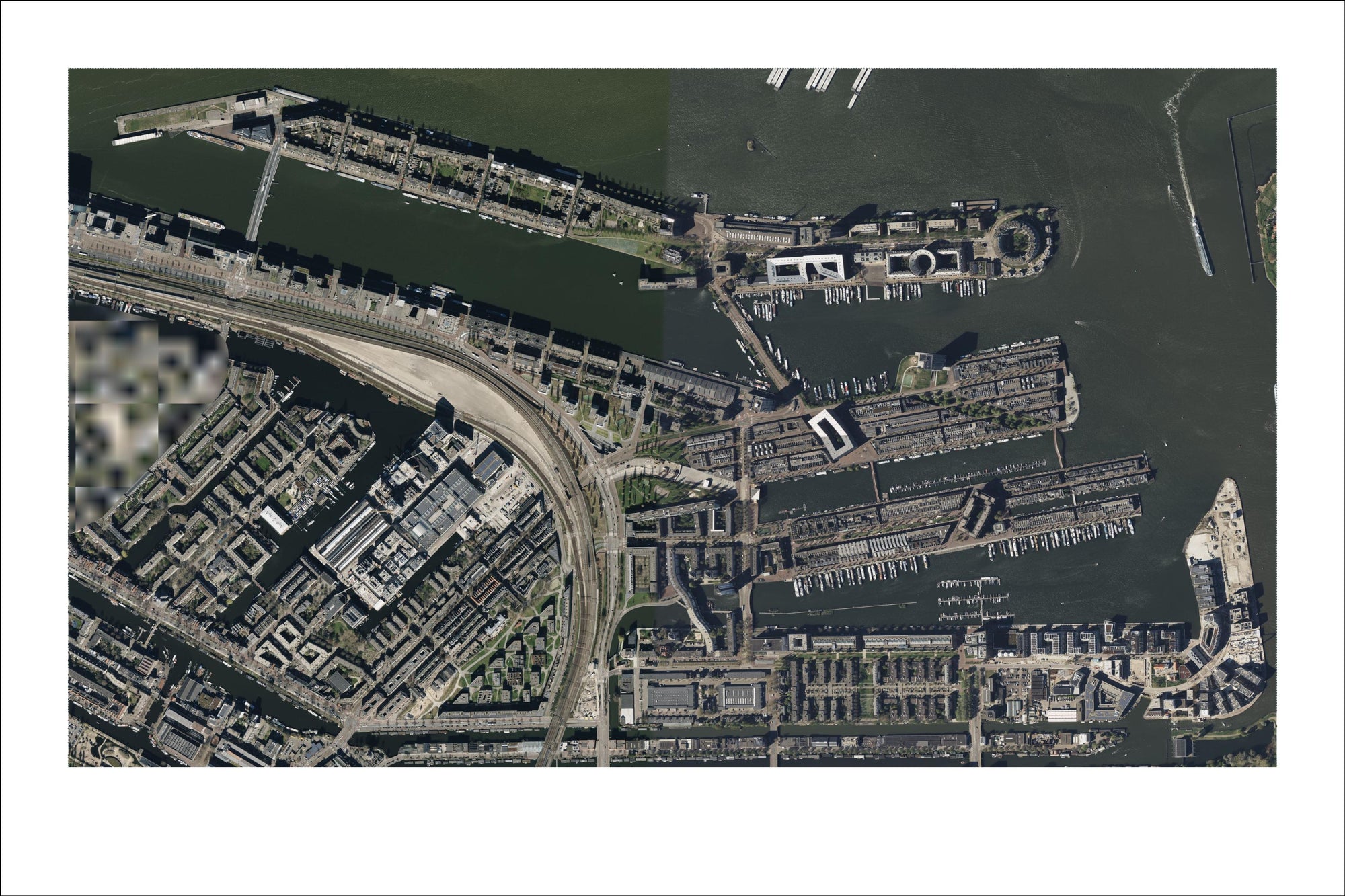

Understand the topology of the area with the help of some aerial pictures and satellite images.

Understand the topology of the area with the help of some aerial pictures and satellite images. - In this case we are looking at the Eastern Harbour District in Amsterdam.

In this case we are looking at the Eastern Harbour District in Amsterdam.

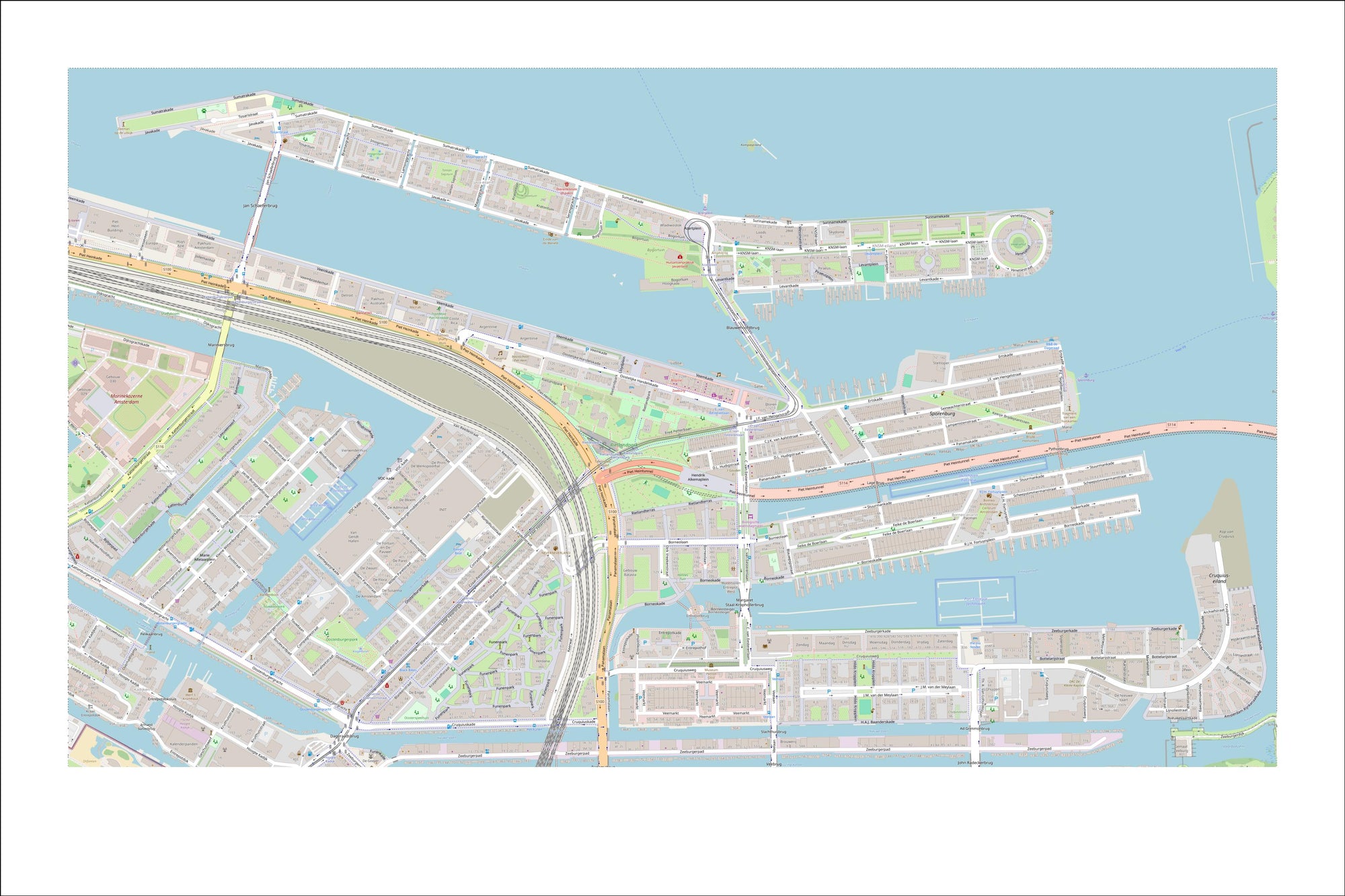

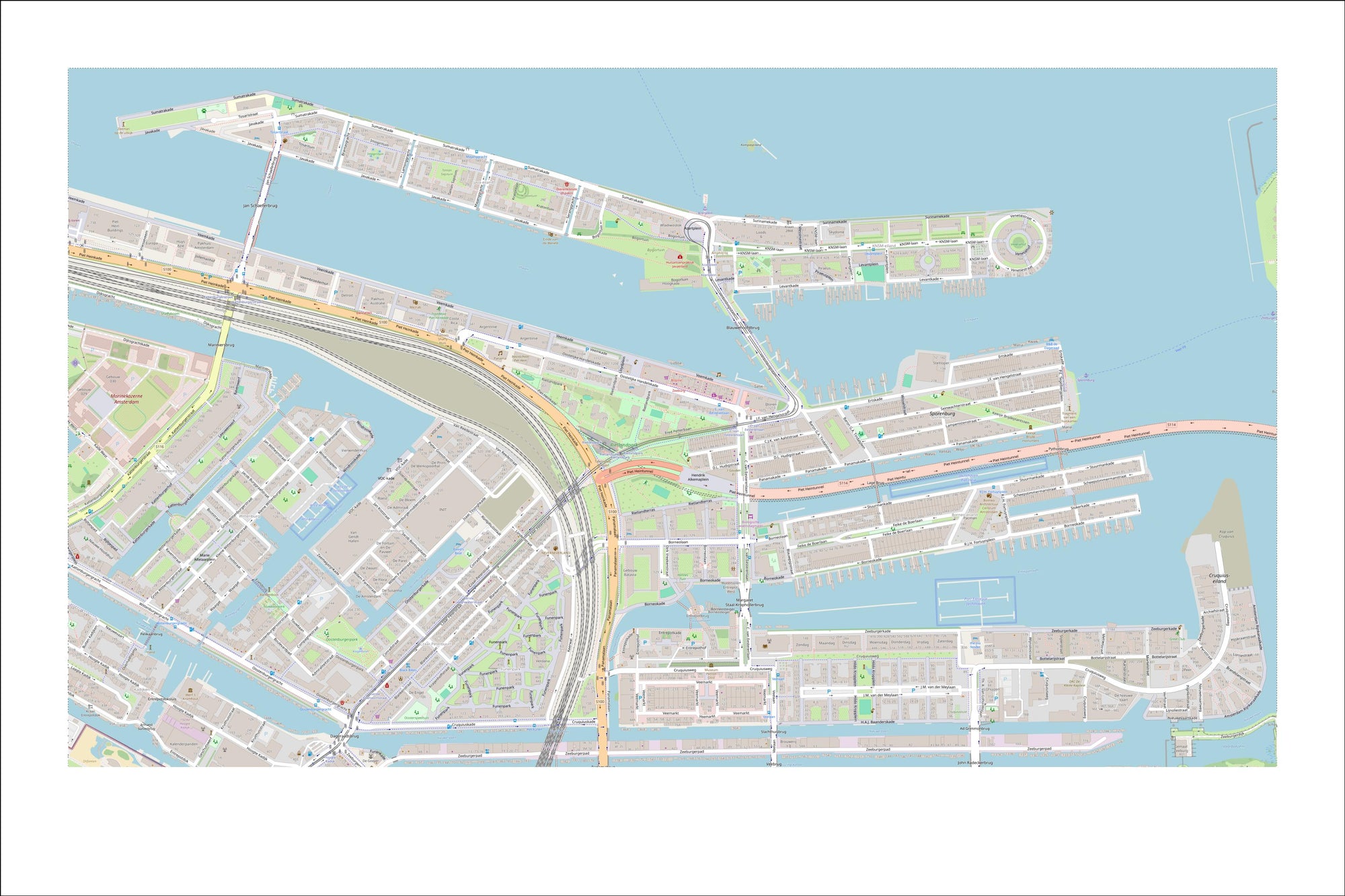

In this case we are looking at the Eastern Harbour District in Amsterdam. - The map provided here by OpenStreetMap is one of the most important sources.

The map provided here by OpenStreetMap is one of the most important sources.

The map provided here by OpenStreetMap is one of the most important sources. - A recent satellite image is used to verify the map and potentially missing green zones.

A recent satellite image is used to verify the map and potentially missing green zones.

A recent satellite image is used to verify the map and potentially missing green zones.

Data fusion

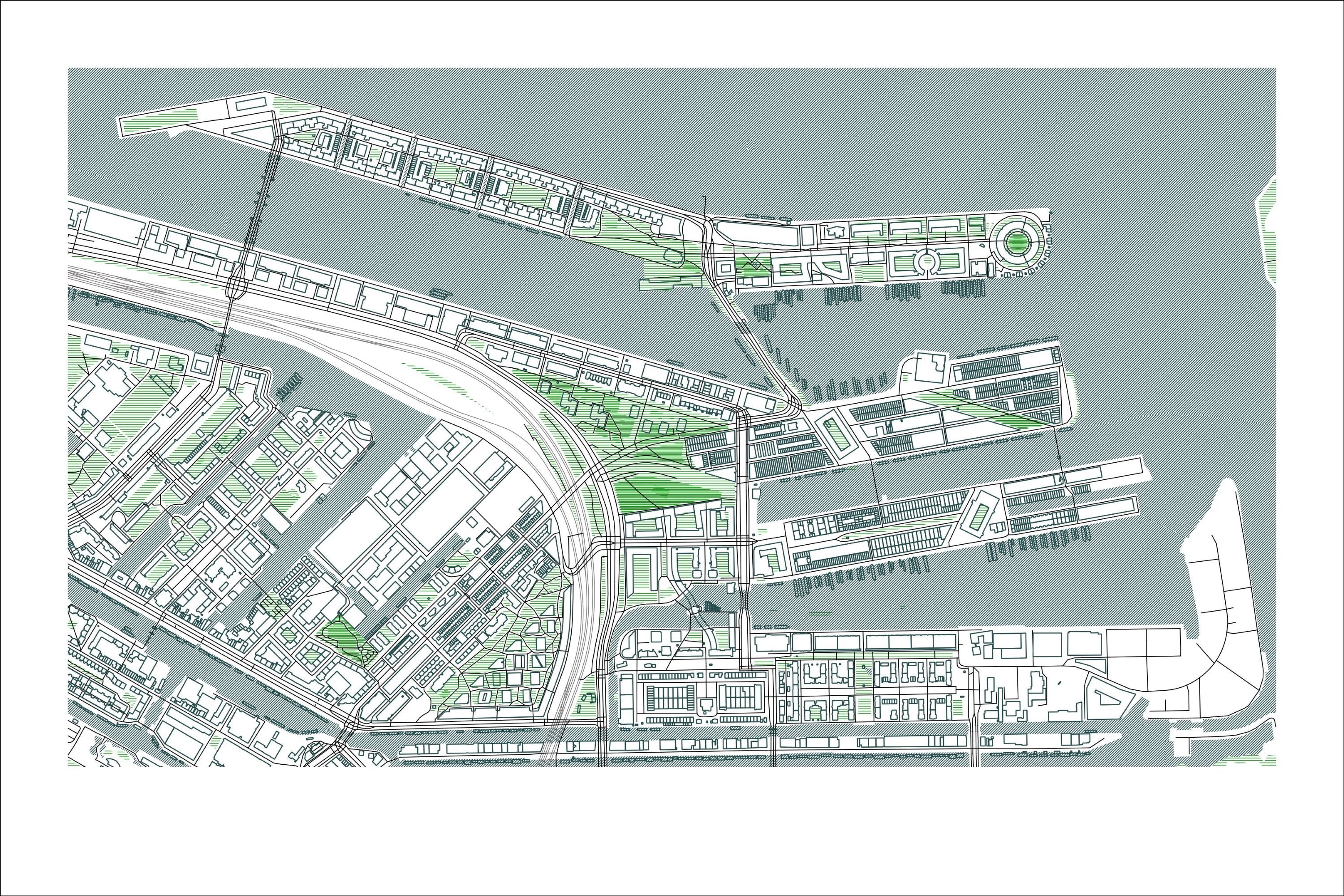

The base of the design is rooted in reality and therefore we use geographic data of various sources. For greenery we make use of satellite images and park data, whereas the roads are mainly from OpenStreetMap.

Design

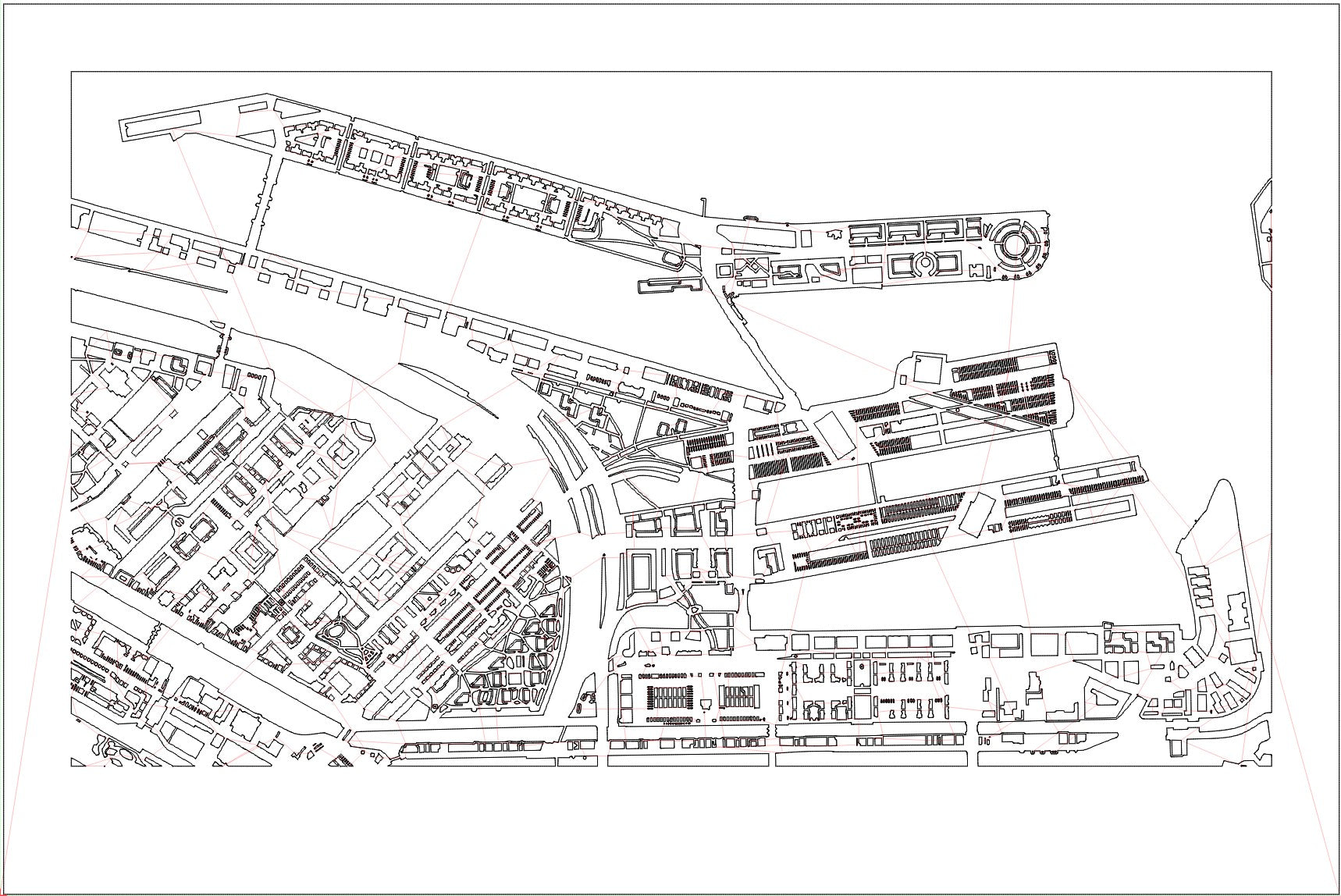

Fusing and visualizing the raw data in Geographic Information Software aids in the design process.

Material and Colour selection

Information layers are visualized to aid in the design process. In this phase I decide on the area and scale. In addition I manually add or edit details depending on the project. Here it involved adding boardwalks to houseboats and building outlines not yet in the national registry.

Design choices and material limits

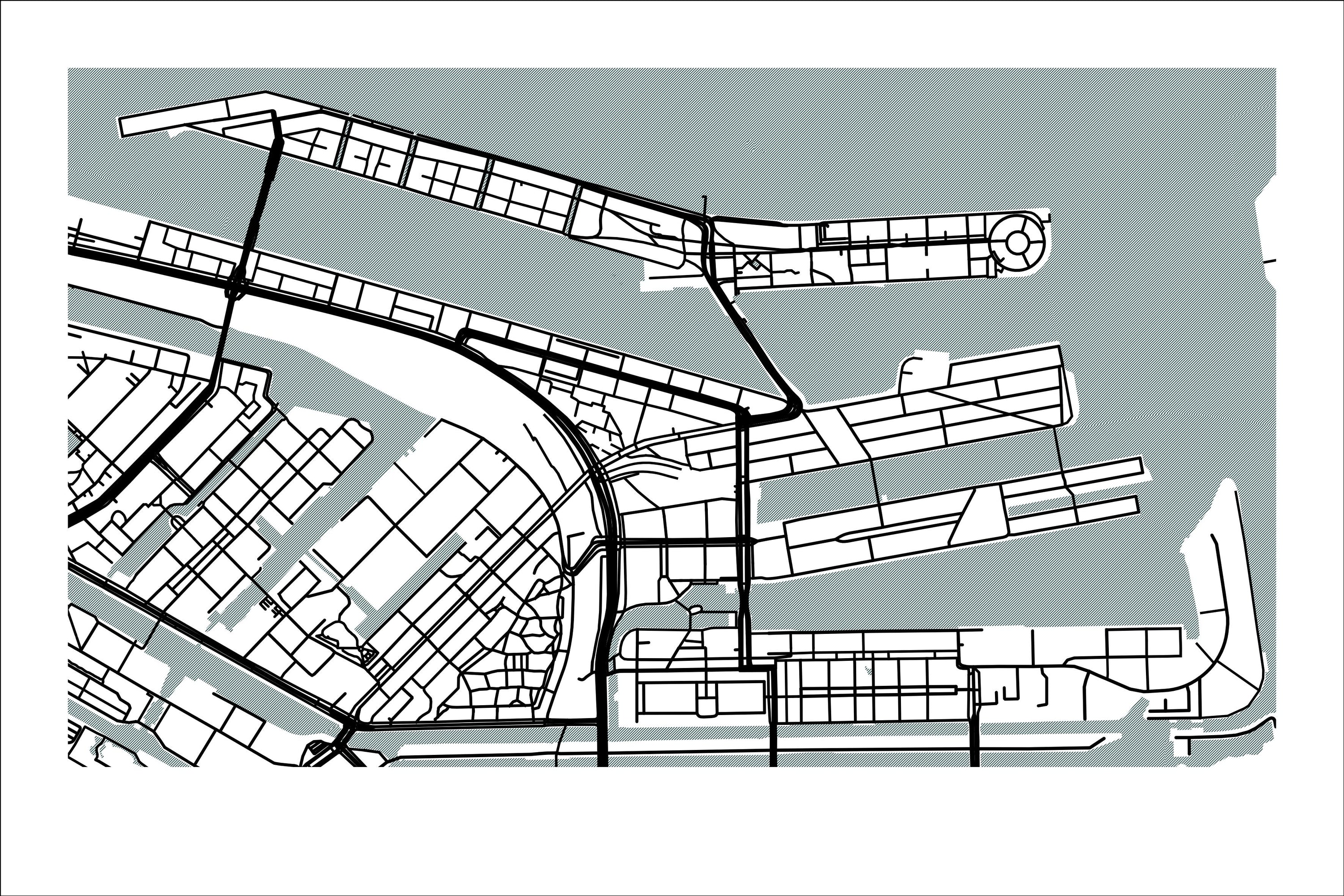

Several design choices are made such as the width of the roads. This is a delicate balance between, a realistic view, esthetic value and the technical limits of the materials.

Preparation for cutting

Toward the manufacturing phase I split the design up in 5 layers. All are vectorized and translated in machine code.

Realizing the Design

Material and Colour selection

Combining wood species, paper colours and textures is essential in obtaining the most pleasing results. Countless hours have been spend on Colors study, searching for the best combinations. To gain more insight in the materials have a look at our materials page.

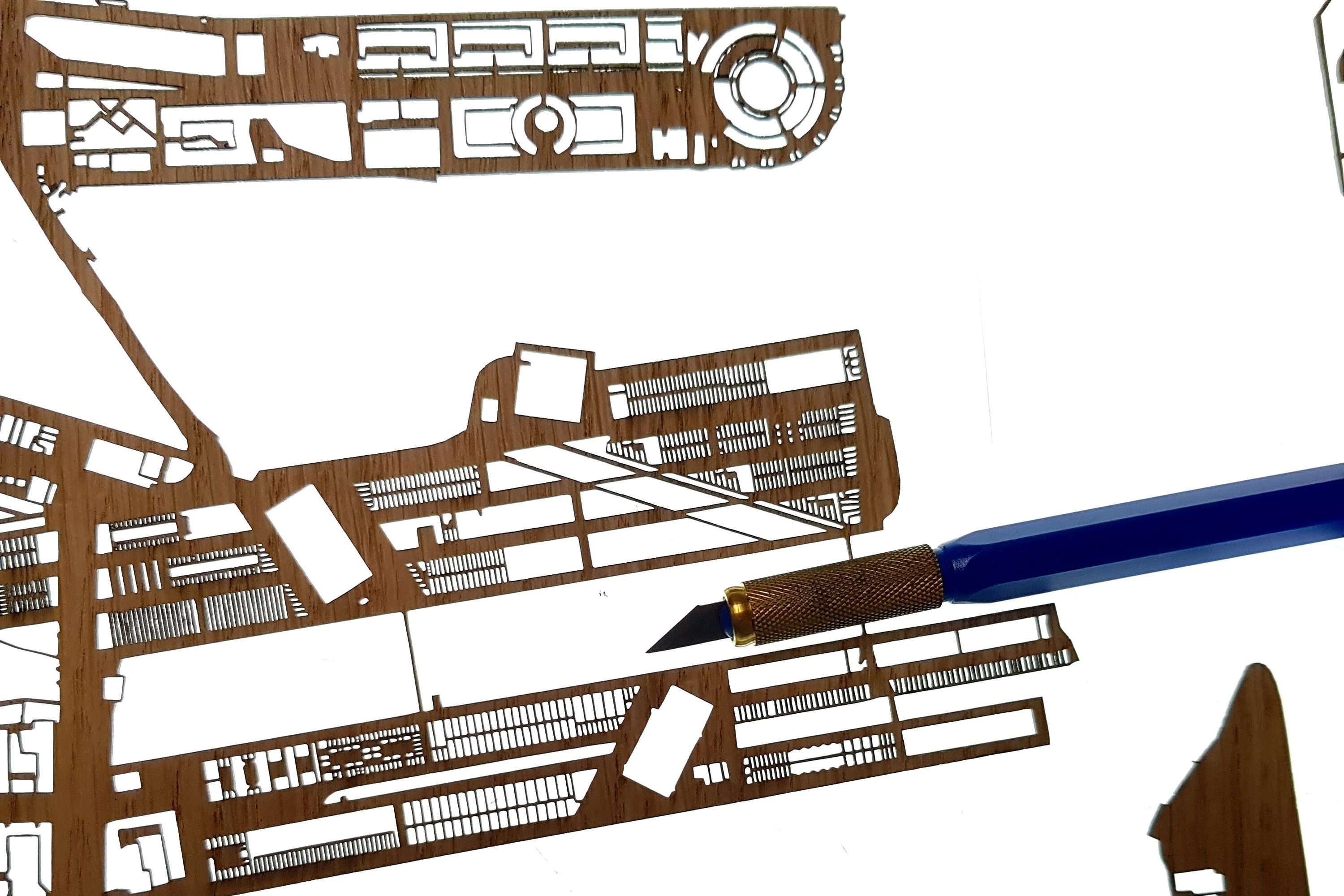

A peek at the cutting process

To obtain my desired level of detail I've integrated my own cutting machines which are able to cut with extreme precision and a very clean surface result. For some layers this can take up days to cut all individual buildings.

Inspection and cleaning

At the end of the cutting process all layers are put on a glass plate to check for any small faults. These are repaired by a manual process and all layers are gathered for glueing.

Bonding and varnishing the layers

The glueing, which is done manually, requires a steady hand to perfectly position the delicate layers.

The Final work

I hope you enjoyed this case overview where we went from concept all the way to the eventual result.

Underneath you can find more information on this specific work.

Eastern Harbour District

Amsterdam

475*325mm

Limited edition (25)